The launch of Bambu Lab H2D marks the deep integration of 3D printing, laser engraving, CNC, and other technologies. Tyvok is also following this trend, promoting the application of laser technology in multi - functional manufacturing equipment.

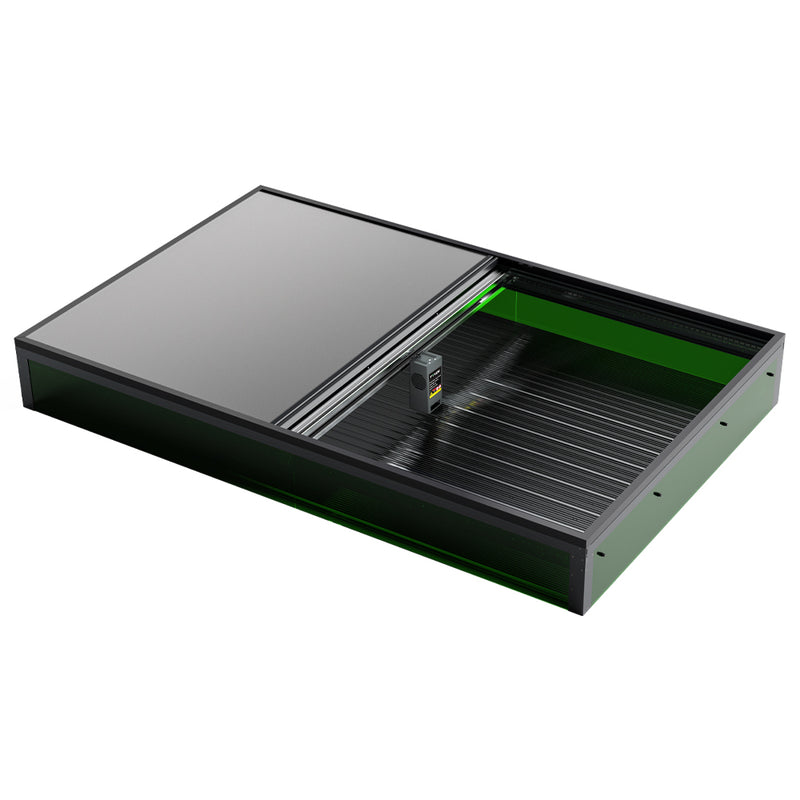

Compared with traditional desktop laser engravers, Tyvok's products demonstrate more powerful advantages in large - scale processing, adaptability to industrial - grade materials, and intelligent control.

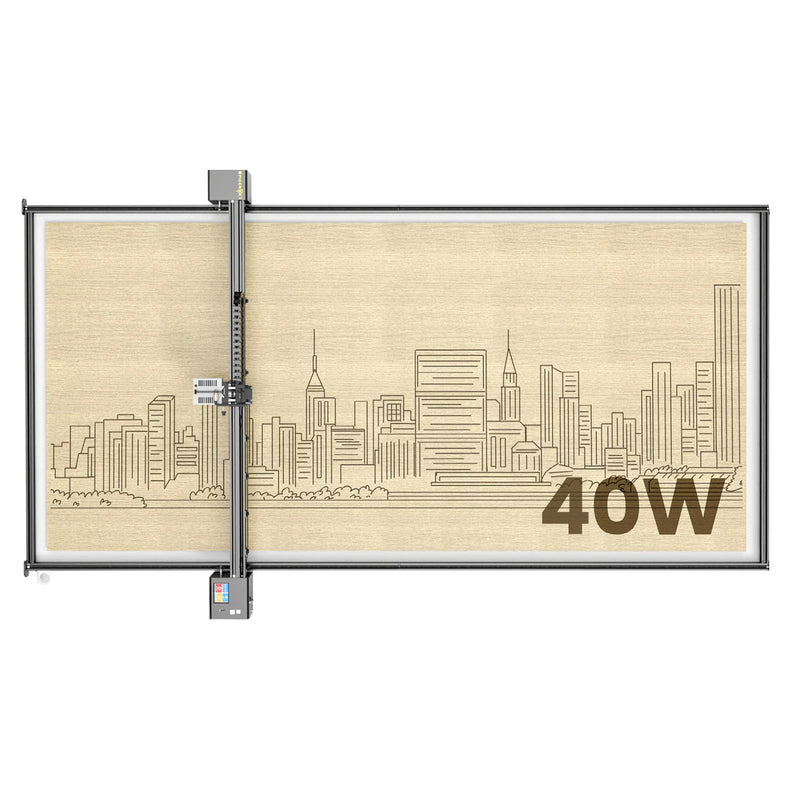

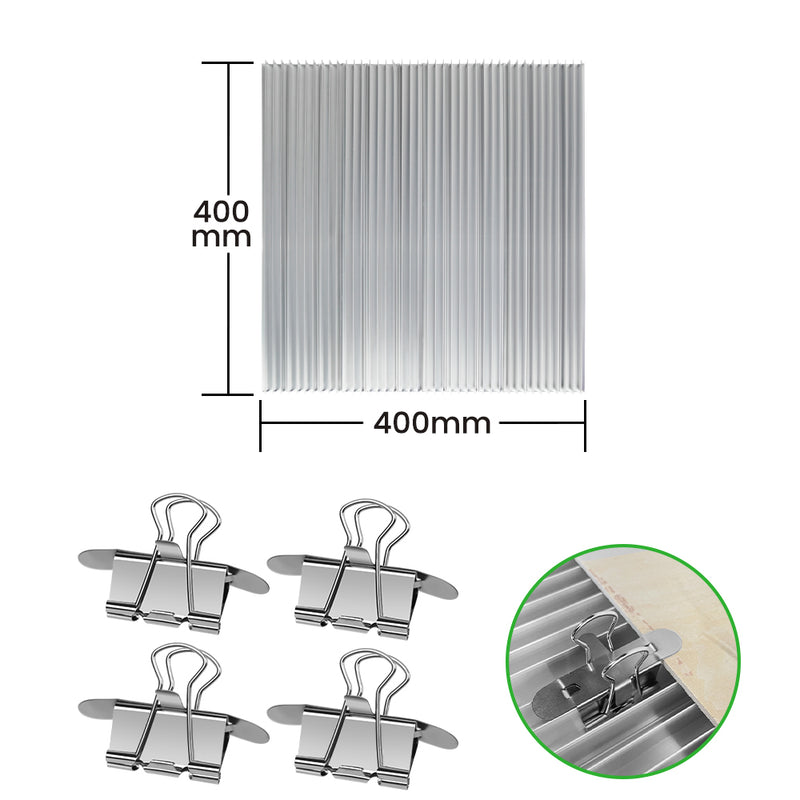

For example, the Tyvok S1 features an extra - large working area of 4'11" x 8'2" (1300x2440mm). It supports precise engraving and cutting of various materials, including wood, metal, plastic, and glass, and is well - equipped to handle more complex commercial applications.

In addition, Tyvok's infrared laser modules, such as the 2W 1064nm pulsed laser, perform outstandingly in the field of metal engraving. Compared to blue - light lasers, they can achieve more delicate and higher - contrast engraving results. This makes Tyvok equipment suitable not only for makers and designers but also provides efficient solutions for industrial production, personalized customization, and commercial processing.

Moving Forward Hand in Hand, Sharing Technological Transformations

In today's evolving manufacturing industry, Tyvok remains committed to technological innovation and promotes the integration of laser engravers with diverse manufacturing technologies like 3D printing and CNC machining. We look forward to deepening cooperation with industry partners like Bambu Lab to explore the infinite possibilities of cross - border manufacturing and enable laser engraving technology to empower more creative scenarios.

In the future, Tyvok will continue to focus on high - power, large - format laser technology, intelligent software control, and safety system optimization, bringing higher - quality and more intelligent laser engraving solutions to global users.

Let's march towards a new era of manufacturing, jointly opening up a more free, efficient, and creative future!